The programs which supply positioning information to this control for machining blisk airfoils were developed with APT and special programming techniques that were devised for these programs. Blisk Area Clearance rapidly removes material on a blisk or impeller. The blisk strategies are: Blade Finishing finish machines the blades. This manufacturing process is a feasible alternative for closed-type blisk and impellers (Figure 5), known as shrouded blisk, integrated impeller and hooded. Note: Blisk strategies are only available in PowerMill Ultimate. This machine is directed by advanced computer numerical control. The Blisks category on the Strategy Selector dialog contains the area clearance and finishing strategies required to machine a blisk or impeller.

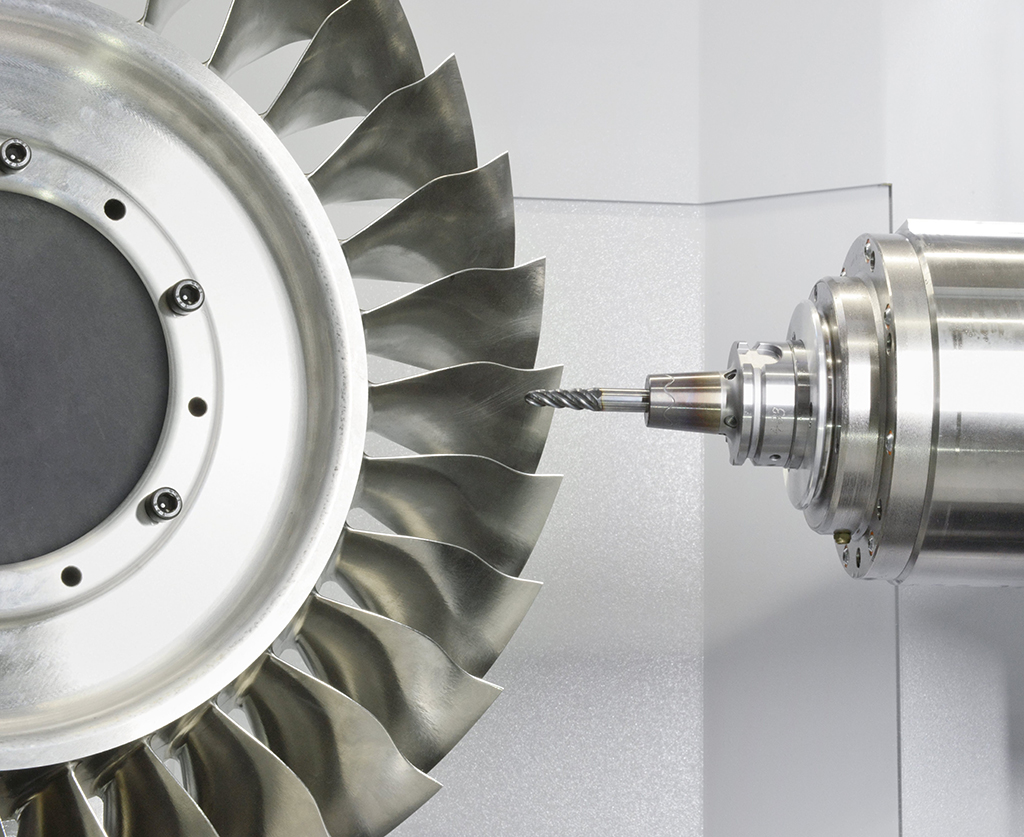

A new milling machine was designed for this process, which machines four identical parts simultaneously. Five-axis precision contour milling was developed to machine the airfoils of the five axial flow blisk stages and the impeller, all of which are integral with their supporting disk. Abstract: Integral bladed rotors (IBRs), such as impeller and blisk, have become five-axis machining reference components. Impellers and Blisks centrifugal pumps axial variable pitched pumps shrouded impellers paddle applications backward curved propellers and turbo charger.

#Impeller blisk manual

Processes which were previously available, and which were used to produce airfoils for development engines, were too costly and too dependent on manual skill to meet volume production requirements. Although there are many machining trajectories applicable to blisks and. In the latest technical corner, Paul and Gio review the GRUPPO PARPAS - Unika range of machine tools supplied from Leader CNC Technologies in the UK.They dis. This development was carried out under a Manufacturing Methods and Technology contract awarded by the Army Aviation System Command, which later became the Army Aviation Research and Development Command AVRADCOM, to the Aircraft Engines Business Group of the General Electric Company in Lynn, Massachusetts. based impeller machining strategy) created for machining process planning 11. Highly automated processes were developed to machine and control the quality of airfoils on the blisks and impeller which are the principal rotating components of the compressor for the T700-GE-700 engine, which powers advanced military helicopters. Highly automated processes were developed to machine and control the quality of airfoils on the blisks and impeller which are the principal rotating.

0 kommentar(er)

0 kommentar(er)